The process of sterilizing surgical instruments is a relatively young one, having been around for only about 100 years. In that time sterilization technology has however, developed quite quickly. The driving force behind this has been the common law requirement of a duty of care, leading to standards such as AS/NZS 4187: 2014 and NSQHS.

Along with the maturing of these standards has come the requirement to more effectively trace surgical instrument through the sterilization process to their end use on a patient.

Electronic Tracking Systems are the best choice for Tracking.

TABLE OF CONTENTS

Download our Free eBook

The Definitive Guide to Surgical Instrument Tracking

Part 2: Electronic Tracking Systems

Just fill out the form and we will send it to you now

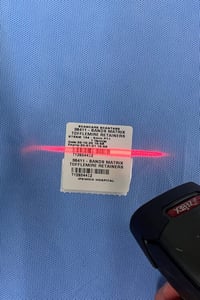

Typically, an electronic system utilises barcode labels and scanners. Barcode labels representing instruments and trays are printed from a barcode label printer. The barcode labels are attached to the packs containing the instruments.

Barcode labels that identify staff and the sterilizer are also created from the system.

In Simple terms the barcodes on the instrument packs are scanned by the instrument technician, who then scans a barcode that represent a sterilizer, and finally scans a barcode that represents themselves.

As the barcodes are scanned, timestamps are taken by the tracking system and provide the name of the technician, the name of the instruments and the name of the Sterilizer that instruments were sterilized in and the date and time it all happened.

Electronic Instrument Tracking Systems utilise a number of hardware items to create and record data.

The main items are:

- Computer Servers & Workstations

- Barcode Label Printers & Barcode Label Stock

- Barcode Scanners & Barcodes

- A4 Printers

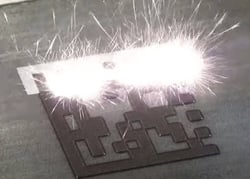

- Laser Etching Machines

You may not know it, but if you work in a healthcare facility, you will most likely have a room like this located somewhere in your IT department.

This server room contains servers which are similar to Computer Workstations except larger and far more powerful.

These servers house all the applications and data that you use on a daily basis when you use your work computer.

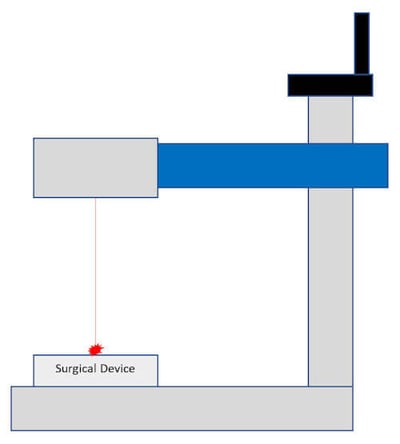

This diagram illustrates the basic concept of a Computer Network.

The Servers housing the applications and data are located in a room protected by security. The computer workstations are connected to the servers by way of Cabling or WIFI.

When a user accesses a program on their computer the data is retrieved from server, displayed on the workstation and then saved back to the server.

Electronic Tracking systems generally use this type of 'Server' & 'Client' setup. When you scan a barcode into a field in the Tracking application, the tracking application will send your data to server where it is processed and saved.

The data on the servers is backed up daily and generally stored in a secure location so it can be restored in the event of a system failure.

DIRECT THERMAL PRINTERS

Direct Thermal, commonly referred to as a Receipt Printer, prints out labels with a look and feel similar to the receipts you get from your local supermarket.

Direct Thermal means the label stock has a coating on it that turns black when it passes over the printer head. The coating turns black in the areas where it is heated, producing text or images.

These printers are not siutable for printing barcode labels for processing through Sterilizers as the heat of the sterilizer will turn the coating of the entire label black.

THERMAL TRANSFER PRINTERS

Thermal Transfer Printers on the hand do not use a label stock that has a heat sensitive coating.

A Black ribbon is melted onto the label as it passes over the printer head.

These printers are siutable for printing barcode labels for processing through Sterilizers as the heat of the sterilizer will not affect the label.

Labels are also available in green which is cellulose free designed to be compatible with low temperature hydrogen peroxide sterilizers and polypropylene (plastic) that can withstand both Sterilizer and Thermal Disinfecting processes.

The type of barcode scanner you need depends on the type of barcodes that need to be scanned.

There are many different type of barcodes and not all scanners will scan them all.

Barcodes are generally either wide with a vertical mixture of black and white bars (Linear) or square with different configurations of black and white square dots (2D).

Linear barcode SCANNERS

image SCANNERS

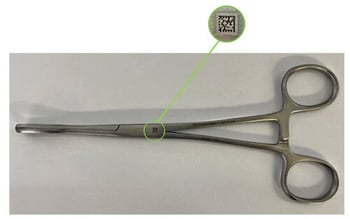

Image scanners (commonly also known as 2D scanners) work differently to linear scanners as they are in fact a Camera. They basically take a photo of the barcode and then decode it using the smarts in the scanning device.

The red flood of light acts as a mechanism to diffuse the light that reflects of the surface of the object. This is particularly useful when scanning highly reflective Surgical Devices.

There are 2 main ways that scanners connect to and communicate with a computer:

- Directly by a USB cord (USB Corded Scanners)

- Indirectly by a USB cord from a docking station (Wireless Scanners)

USB CORDED SCANNERS

These scanners connect to directly to a computer via a USB connection. The generally have around 1.5 metres of lead and which restricts scanning barcodes to within the area that the lead can reach.

USB Corded scanners are available in 1D and 2D models (including 2D Data Matrix Instrument Scanners) and some come with stands.

WIRELESS SCANNERS

Wireless Scanners connect indirectly to a computer via a USB connection attached to the docking station where the scanner sits and charges.

The scanner and Docking station are connected via wireless methods such as Bluetooth and generally have a communication range of around 30 metres.

These scanners are available in 1D and 2D models (including 2D Data Matrix instrument scanners)

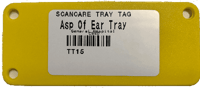

Tray Tags have been around for a long time. They are used to identify Instrument Trays.

In Electronic systems, the purpose is the same however the barcode can be used for tracking at Setup & Packing and into Washer Disinfectors.

Tray Tags effectively simply and streamline the Tracking process.

Chances are you may have one of these at home.

Document Printers come in 2 varieties:

- Ink Jet

- Laser

Electronic Tracking Systems use these printers to print Tray Lists at Tray Setup and to print reports.

Ink Jet printers use a water-based ink which will run when subjected to the Sterilizing environment.

Laser Printer ink is heated onto the paper surface and does not run in wet environments.

Laser Printers are the preferred printer for use in Electronic Tracking Systems.